Over the years I’ve brewed lots of different IPAs. Lately however, I’ve been focused on developing Single Tap, my house IPA. This third generation recipe has its roots in a beer I brewed back in 2012 which won a first place ribbon in the first round of the National Homebrew Competition. Over the years, the recipe has been simplified, with the notion that every ingredient should have a justifiable reason for its inclusion. While the recipe is always changing, the heart of this beer is focused on providing a toasty, yet lean, highly-attenuated malt background and contrasting it against a ton a big American hop flavor and aroma. I am able to keep the bitterness low compared to other IPAs by pushing attenuation to the point that little bitterness is needed for balance.

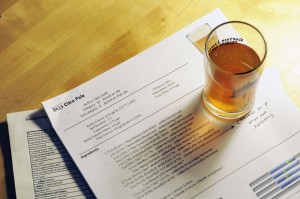

Single Tap IPA 3.0 Recipe

Size: 4.32 gal – With system and trub losses, I typically end up with 2.75 gallons in the fermenter.

Efficiency: 72% (Measured)

Attenuation: 82.8% (Calculated)

Original Gravity: 1.070 SG (Measured)

Terminal Gravity: 1.012 SG (Measured)

Color: 9.71 SRM

Alcohol: 7.6% ABV (Calculated)

Bitterness: 24.0 IBUs – Calculations don’t take into account bitterness gained through whirlpool additions, which is considerable.

Fermentables:

5 lb (45.5%) – Briess 2-Row Brewers Malt

3 lb (27.3%) – Crisp Maris Otter

1 lb (9.1%) – Weyermann Vienna Malt

8 oz (4.5%) – Briess White Wheat Malt

6 oz (3.4%) – Crisp Crystal 45

2 oz (1.1%) – Weyermann Acidulated Malt – added for pH correction

1 lb (9.1%) Table Sugar – added during boil

Hop Additions:

4 g Citra™ (13.7% AA) – First Wort Hop

0.5 oz Sterling (7.5% AA) – 10 m

0.5 oz Centennial (10.5% AA) – 10 m

2 oz Citra™ (13.7% AA) – Post Boil Whirlpool – 25 m

3 oz Amarillo® (8.7% AA) – Post Boil Whirlpool – 25 m

1 oz Centennial (10.5% AA) – Post Boil Whirlpool – 25 m

0.5 oz Sterling (7.5% AA) – Post Boil Whirlpool – 25 m

0.5 oz Centennial (10.5% AA) – Dry Hop 3 Days

1.5 oz Citra™ (13.7% AA) – Dry Hop 3 Days

1.5 oz Amarillo® (8.7% AA) – Dry Hop 3 Days

Kettle Additions:

0.5 ea Whirlfloc Tablets – 15 m

0.5 tsp Wyeast Nutrient – 10 m

Yeast:

WYeast 1056 American Ale™ – 1600ml 1.040 starter on stir plate.

Water Additions:

Soft NYC Water

6g Gypsum (Calcium Sulfate)

2g Calcium Chloride

Mash Regiment:

Saccarification Rest – 149° F, 60m

Mashout Rest – 168° F, 5m

Tasting Notes:

Tasting Notes:

Judged as a BJCP Category 14b American IPA

Aroma (11/12)

Putting your nose in this glass unveils a cornucopia of hop-derived fruit aromas. Most obvious is the mango, but there are also big notes of orange, tangerine, and a hint of peach. There is just a touch of grassiness and pine resin. Underneath the hops, there is a light hint of toasty and bready malt. Very clean. Not alcohol or other off-aromas.

Appearance (3/3)

Beer is a slightly hazy and light copper in color. The glass is capped by a frothy white head of exceptional persistence and lacing.

Flavor (15/20)

This beer is bursting with bright hop flavor. There is tons of citrus, some tropical fruit, and just a touch of grass. The beer is extremely dry, but the ripe fruity hops give a slight perception of sweetness. Bitterness is considerably less than most commercial examples and could be bumped up just a touch. Underneath all of the hops is a moderately toasty and bready malt component which is quite nice. The hop flavor carries through and lingers a touch in the finish.

Mouthfeel (5/5)

Medium bodied with a very nice creaminess that finishes clean. Moderate carbonation.

Overall Impression (8/10)

This is the best iteration yet of my constantly evolving IPA recipe. The dryness of the beer melds well with intense juicy hops achieving a balance that makes the beer extremely quaffable. While it could use just a hair more bitterness and perhaps even a touch more dryness, the beer in the glass is a wonderful example of the style. This homebrew easily stands up to the best commercial examples.

Total: 42/50 Excellent